No products

Roto-Finish

Viewed products

-

ROTO-FINISH 200 with...

Rotating diamonds grit size...

Last Product Reviews

ROTO-FINISH 200 with handle, grinding

PTFR200

New product

Rotating diamonds grit size 200 (grinding) plus adjustable handle

More info

Auto rotating diamonds, grit size 200 + adjustable Tuning-File handle.

Sharpening by grinding, especially for edges hardened on the surface (hardened by stones or caused by a too heavy machine sharpening).

The diamond disks rotate automatically by the backwards and forwards movement along the edge. This patented system has three advantages:

-

Through rotation, there is no wear of the diamond in grooves with the risk of rounding the edges.

-

The grinded does not clog the diamond.

-

Grinding is three times quicker.

The Roto-Finish is fixed to the Tuning-File handle. They are available in 4 grit sizes and are supplied with 2 self- adhesive replacement diamonds.

Use of grit size 200 ideally needs finishing with grit size 400.

Pack content

-

1 x Adjustable Tuning-File handle 0° to 6°

(3)

(3)

Steady and accurate handle for: Roto-Finish, Ice-Catcher, files and sidewall plane

58.30 CHF -

1 x ROTO-FINISH 200 without handle, grinding

(1)

(1)

Rotating diamonds grit size 200 (grinding), to be fixed to the Tuning-File handle

86.95 CHF

Reviews (0)

No customer reviews for the moment.

Foire aux questions (FAQ)

- • Diamonds wear less

- • Diamonds stay a little cleaner

- • Diamonds are a little more effective

- • Soiling and dampening of the workplace

- • The base of the ski or snowboard is dirty enough

Yes, and it is even advisable to do it! The Twin Roto Concept is designed for this. This simple and fast way don’t thin the edge so much so it can be sharpened several hundred times before the edge is too thin.

It is advisable to change the rotating diamonds in the following cases:

- for grains 120 and 200: when you grind a lot without great efficiency

- for grains 400 and 800: if they no longer generate a very sharp edge.

It is always a shame to use an abrasive gum that slightly rounds the edge when it is well sharpened.

The ideal is to grind the edge slightly with the long diamond file 400 in the file guide to fall 0.5 ° or 1 ° before sharpening the side edge with Tuning File or Roto finish but very lightly (one to two passages with a very light pressure).

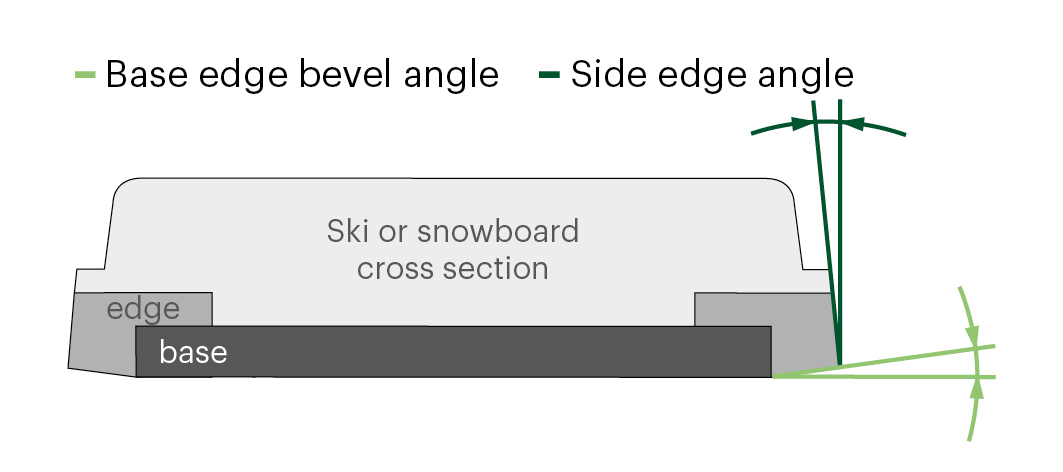

We advise the following angles:

| Base edge bevel angle |

Side edge angle |

|

| Sports, giant slalom, ski cross | 1° | 3° |

| Casual, touring | 1° | 1° |

| Slalom | 0,5° | 3° to 6° |

| Freestyle, downhill, boardercross | 1,5° | 1° to 3° |

The base edge bevel angle comes from the production or service machines in the store. It should be known that 0.5 ° is a very small angle not obvious to reach and that commonly the fall is towards 1 °. For tuning by hand (which is the most accurate) the angle is given by our file guides, which exist in three version 0.5 °, 1 ° and 1.5 °.

With 0.5 ° you have a slightly more responsive ski than with 1 °. Whether your new ski or the previous one you can sharpen with the side angle at 3 °. When you maintain the underside of the edge (which allows good maneuverability and good driving accuracy) and that the edge is rounded or scratched the file-guide 1 ° will more easily remove the abrasions and get a sharp edge. It is better to have a clean edge and sharp at 1 ° than 0.5 ° with more abrasions and a edge that remains a little rounded below.

In summary :

Below: 0.5 ° as long as you work easily to the side of the edge and 1 ° if it becomes difficult to reach the side.

Side of the edge: 1 ° to 3 ° (3 ° is perfect for a slalom ski).

It is interesting to know that for a medium-sized adult a low angulation of the knee of 5mm angles the ski by about 0.5 degree.

Putting a little water on the edges before sanding them has advantages and disadvantages:

The advantages of wet sanding (a sponge is ideal):

The disadvantages of wet sanding:

Unless there are residual wax on the edge, the Roto-Finish diamonds get dirty. On the other hand, fixed diamonds get much dirty. The ideal is to clean each use or every two to three uses and the diamond discs when they look dirty (pull discs to remove).

Always sharpening before waxing!

The ideal is to file the first time and later to use Roto-Finish.

After filing, there is no need to fine-tune with Roto-Finish.

However, for the competition, especially if the snow is very cold and fine a polishing with Roto-Finish 400 then 800 will improve the glide.

When you have skied for a few days on soft snow that has very little rounded edge, it is not necessary to file. You can then limit yourself to three or four trips with the Roto-Finish 400.

When you've been skiing for a day or two on hard snow, you can sharp with the Twin Roro Concept, which consists of 10 to 12 round trips to the Roto-Finish 200 followed by polishing with the Roto Finish 400.

This polishing will be done either by 6 round trips with the roto-Finish 400 set to a degree less than the Roto-Finish, or without changing the angle (same angle as the Roto-Finish 200) but with a dozen or so back and forth.

If by 12 round trips to the RF200 you have not found the cutting edge, add some back and forth. If it is still not sharp it means that your edge is quite rounded and it is better to make a sharpening file.

In general, if you don’t do frequent sharpening use the file.

This is a personal practice that also varies depending on the ski models and / or the quality of the snow. Some do not round, others little and others more and this on different lengths. In general, we avoid rounding skis slalom and personally I do not round in heel even when it comes to longer skis.

For snowboards, it is advisable to round the front of the edge "front side" about 15 cm.

Also look question “Is it necessary to remove the lip with an eraser after using the Roto Finish for sharpening the edges of skis or snowboards?”